Summarize:

DZ400-2D is featured by automatic processing of vacuuming, sealing, printing, cooling, which is used in vacuum packaging for the food ,pharmaceutical, aquatic, chemical and electronic industries. It can prevent the products from oxidization and mildew, as well as corrosion and moisture, keeping the quality and freshness of the product over a prolonged storage time.

DZQ400-2D fills the packaging bag with some kind of gas, such as nitrogen, after vacuuming the bag. It is featured by automatic processing of vacuuming, gas filling, sealing, printing, cooling, which is used in vacuum packaging for the food ,pharmaceutical, aquatic, chemical and electronic industries.

Specification

|

voltage |

220V 50/60Hz |

|

power |

1.5KW |

|

workroom size |

420X440X80mm |

|

sealing length |

400X10mm |

|

sealing speed |

1-4 times/minute |

|

weight |

105kgs |

|

External size |

660X600X1050mm |

- See more at: http://ding-ye.com/Single-chamber-vacuum-(gas-filling)-packager-p145.html#sthash.7W5PX972.dpuf

Custom Field︰

Technical Characters

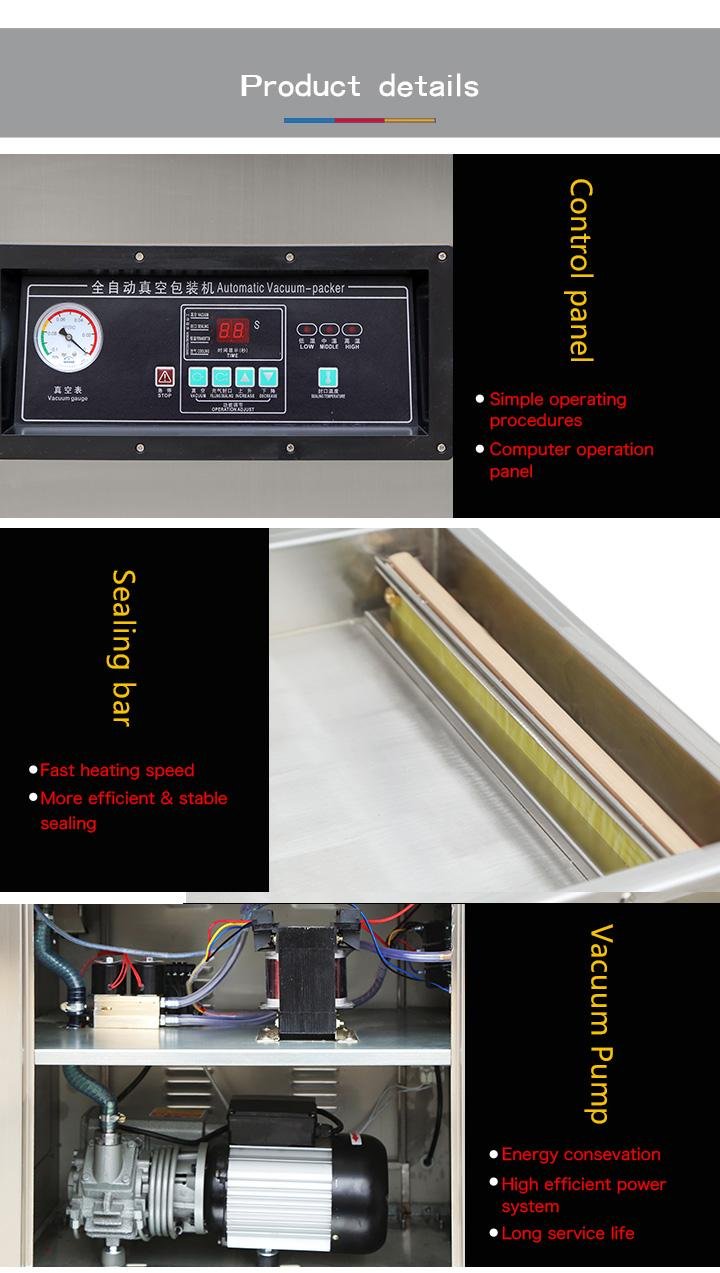

1.Control System: Computer Control Panel, there are many control manner for

customers selecting

2.Vacuum Pump: strict quality examination systom insured the heat of vacuum

packaing machine runned smoothly (Different brand and exhaust ports of

vacuum pump could be configured according to customers specifications)

3.Machine Lid Gemel: Special designed gemel device of machine lid which could

reduce the working intensity dramatically in daily working life

4.Shake Avoiding System: A special designed shake avoiding device used in

machine which will reduce the noise when machine working

5.Main structure’s material: Main structure’s material of vacuum packaging

machine is 304 stainless steel, which insures the beautiful appearance and

antisepticise under serious cauterization circumstance

6.“V” type lid gasket: The “V” type lid gasket is made from high density material

which prolong the using life and wearable in the daily usage, it’s also reduced

the replacement time and production cost